CASE STUDIES

Frozen Storm Sewer Repair

Repairing Sanitary Pipe That Had A 6 Inch Hole

Rehabilitation Of Ash Sluice Pump Intake Manifolds

Rehabilitating A 36 Inch Surge Vessel

Waterproofing Repair

Rehabilitating Four Risers In A Cooling Water System

Preparing Pipes For Service

Sealing Existing PVC To New FRP Base Liner

Frozen Storm Sewer Repair

Repairing Sanitary Pipe That Had A 6 Inch Hole

Rehabilitation Of Ash Sluice Pump Intake Manifolds

Rehabilitating A 36 Inch Surge Vessel

Waterproofing Repair

Rehabilitating Four Risers In A Cooling Water System

Sealing Existing PVC To New FRP Base Liner

Preparing Pipes For Service

TECHNICAL DATA SHEETS

HydraTite®

HydraWrap®

Marine HydraWrap®

LITERATURE

Marine HydraWrap®

HydraTite®

BLOG POSTS

Games, food and fun at this year’s Christmas party. The Meritage was great as always, their food tasted awesome.

HydraTech employees volunteered at Glenwood Gardens to collect and plant native seeds, supporting environmental restoration and community sustainability.

Newest Videos

![]() 2:06

2:06

Fast Structural Reinforcement

![]() 2:06

2:06

![]() 2:23

2:23

Sealing Stormwater Tanks For A Dublin Data Center

![]() 2:23

2:23

![]() 2:09

2:09

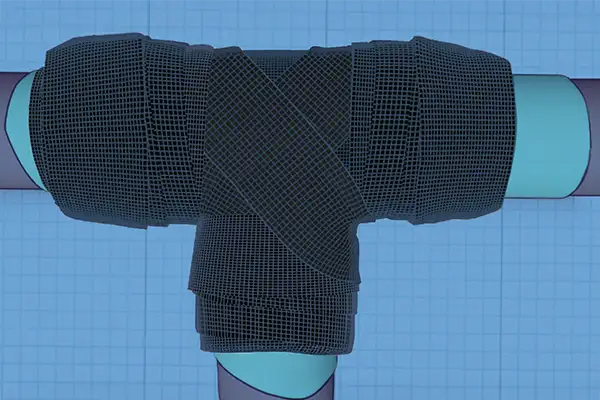

Tee Fitting Repair

![]() 2:09

2:09

ARTICLES

Featuring HydraTite®

Newest Article

HydraTite Internal Joint Seal for Water Supply

A bulk water supply authority was faced with the challenge of repairing leaking joints at points in their network where open channels transition into pipes at river crossings. While the channels are concrete, the pipes are ductile iron and the expansion and contraction of dissimilar materials has been an ongoing source of leaks at the 2000mm diameter joints.

Featuring HydraWrap®

Newest Article

HydraWrap: not Just a Temporary Repair Anymore

September, 2014

Many vessel operators that experience leaks to piping, pipe fittings, and bulkheads have, in recent years, turned to the HydraWrap system. Used to repair leaking pipe systems and prevent downtime, the HydraWrap system, manufactured by HydraTech Engineered Products, LLC in Cincinnati, OH, utilizes high strength carbon fiber fabric and high strength…

Updates

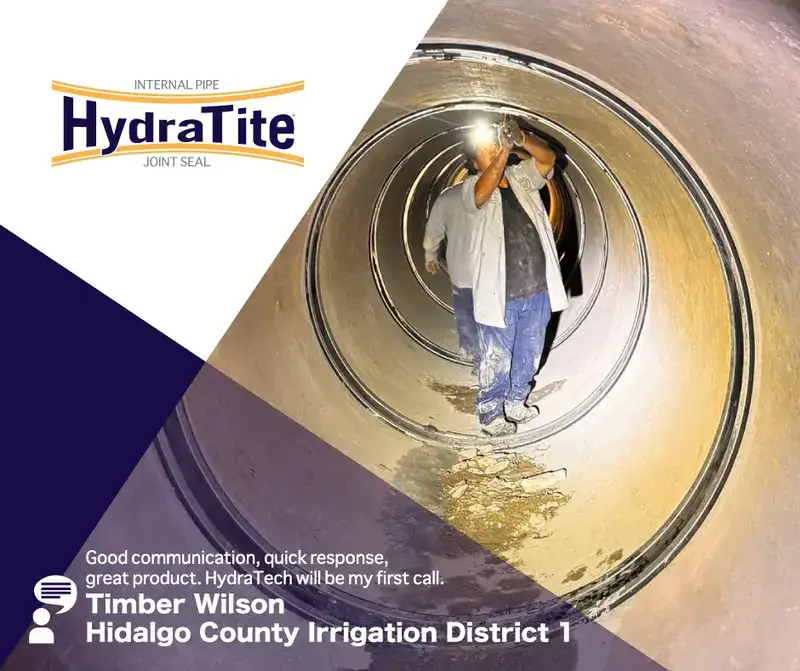

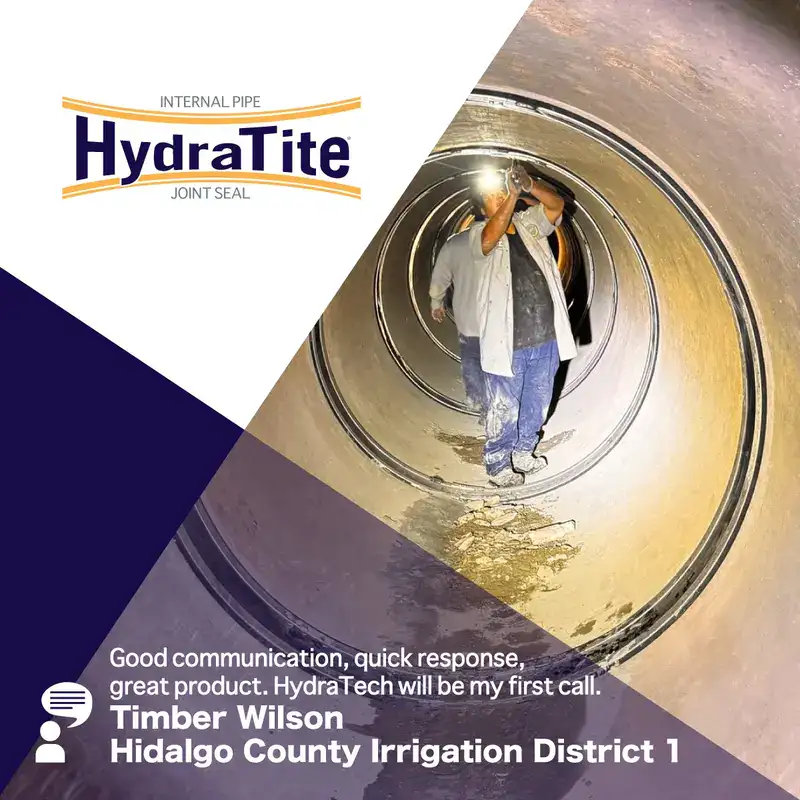

HydraTite was recently shipped down to Texas to seal 8 joints in a 72″ reinforced concrete pipe. Special thanks to Timber Wilson with the Hidalgo County Irrigation District, who took the time to give us this testimonial.

#HydraTite, #HydraTech, #PipingProfessionals, #DontReplacePiping, #RepairOverReplace, #PipeSeal