Social Media Posts

Website Updates

Caleb’s position has shifted a good deal over the years at HydraTech. In this recent blog post, he recaps some of the roles he has played in helping the company succeed.

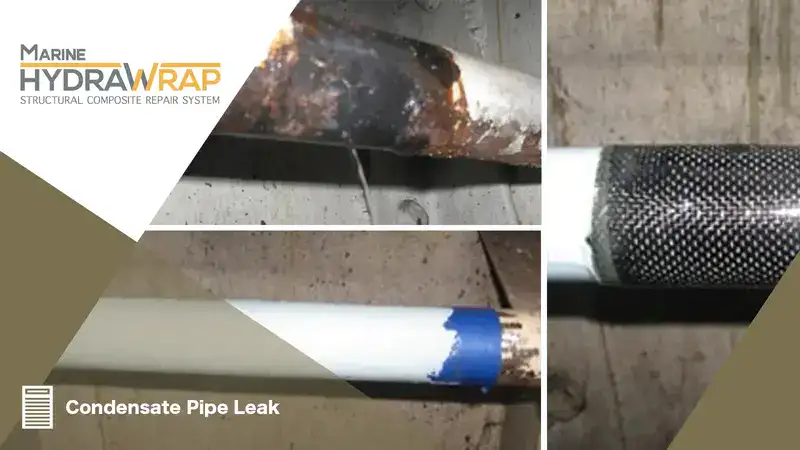

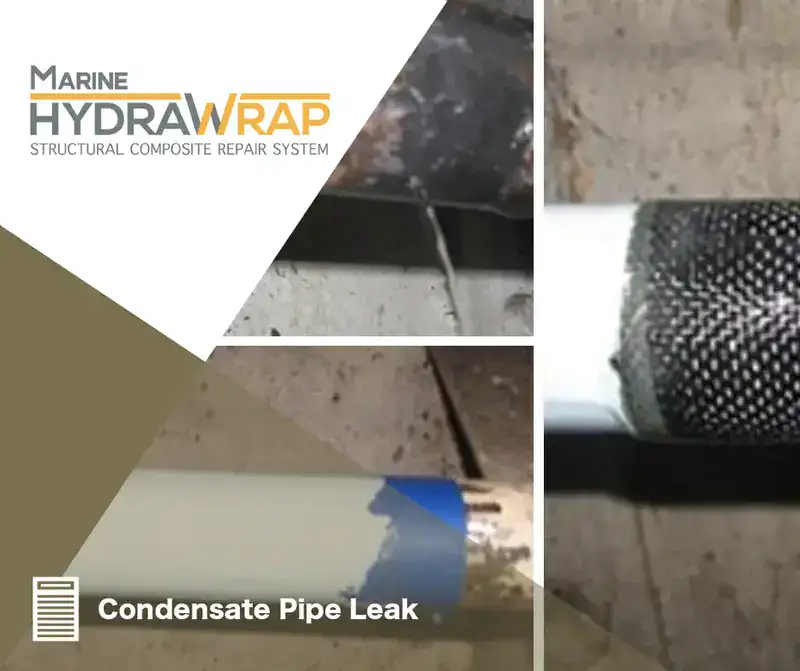

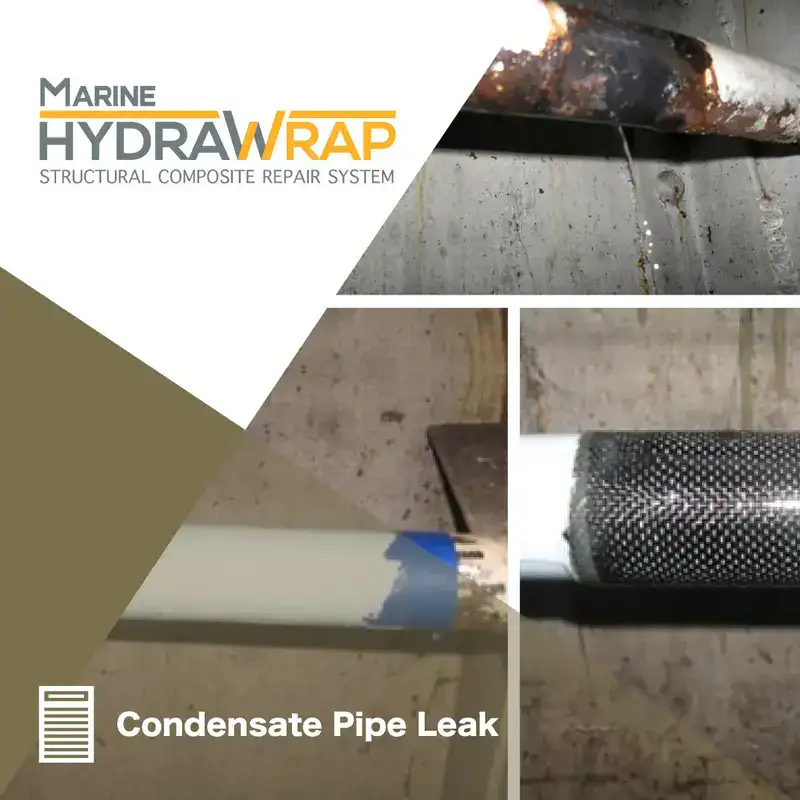

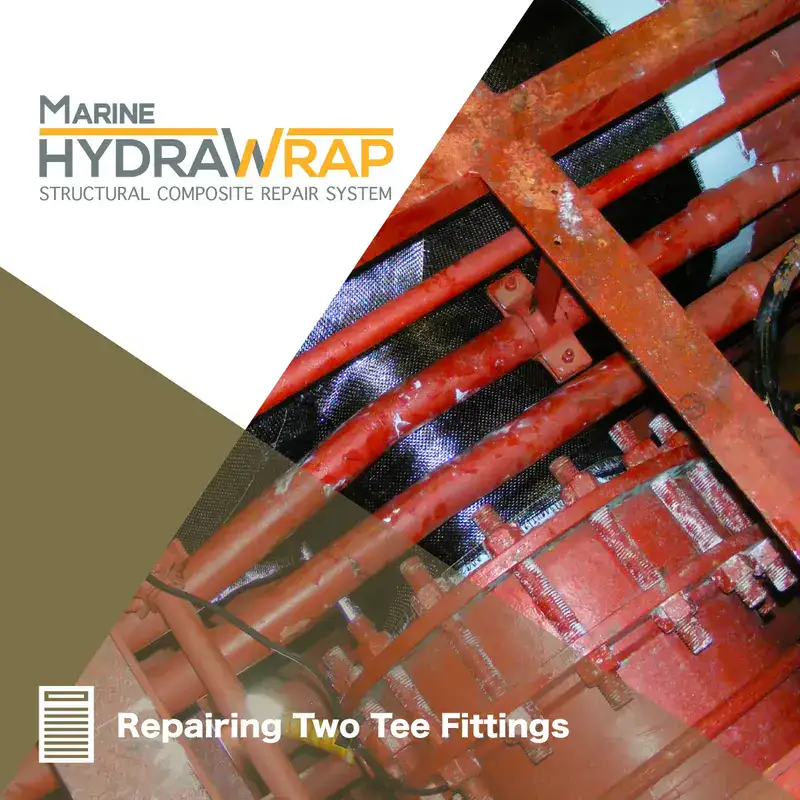

This extensive rehabilitation project, HydraWrap was applied to nearly 100 repair points. Our flexible composite repair system was used to stop leaks in elbows, tee fittings, flanges, and straight portions of pipes.

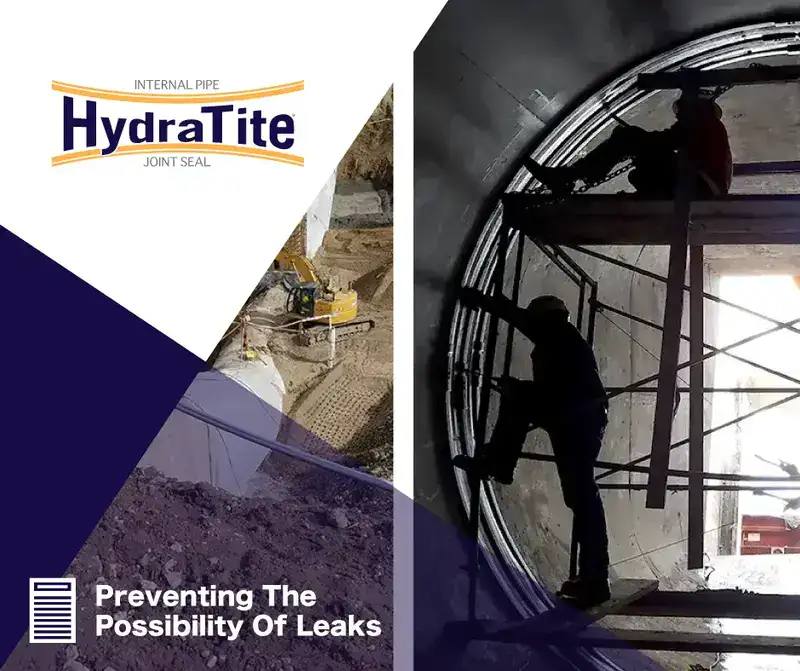

A new school was being built in Iowa atop pipes laid in 1937. In very little time, these two pipelines were fortified against infiltration and prepared for the anticipated increase in use with HydraTite seals.

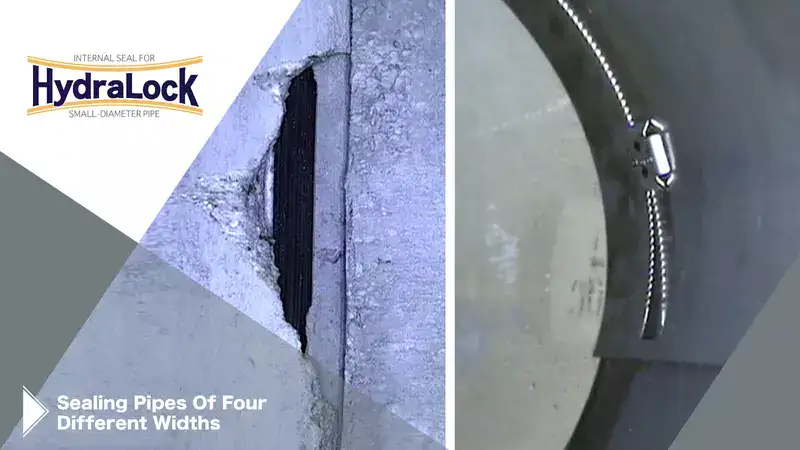

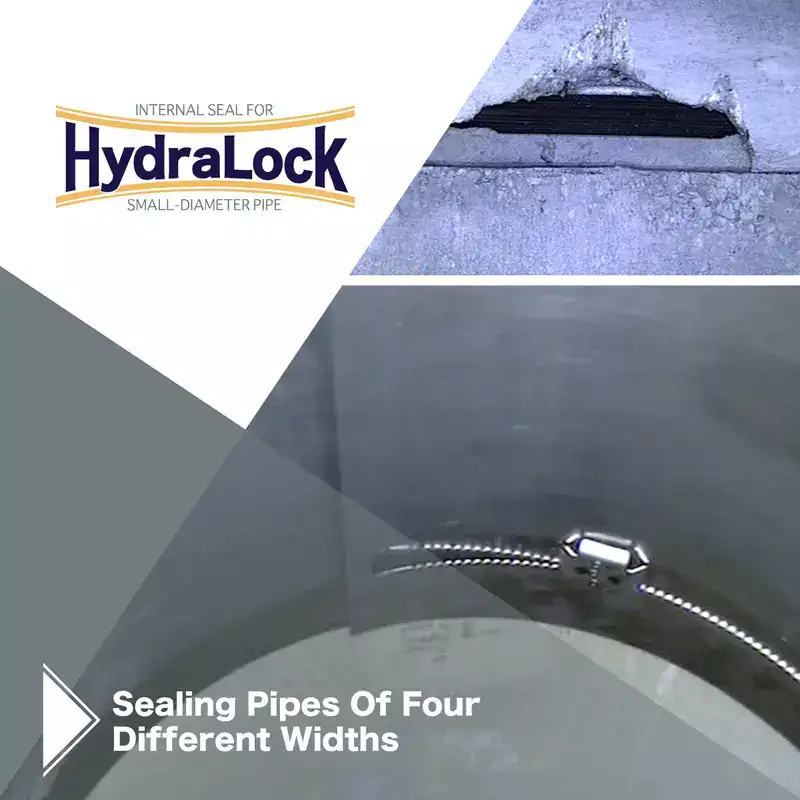

A pipe rehabilitation project for MnDOT involved sealing 4 joints in 48″ and 72″ drainage pipes. The project was completed with only two crew members.

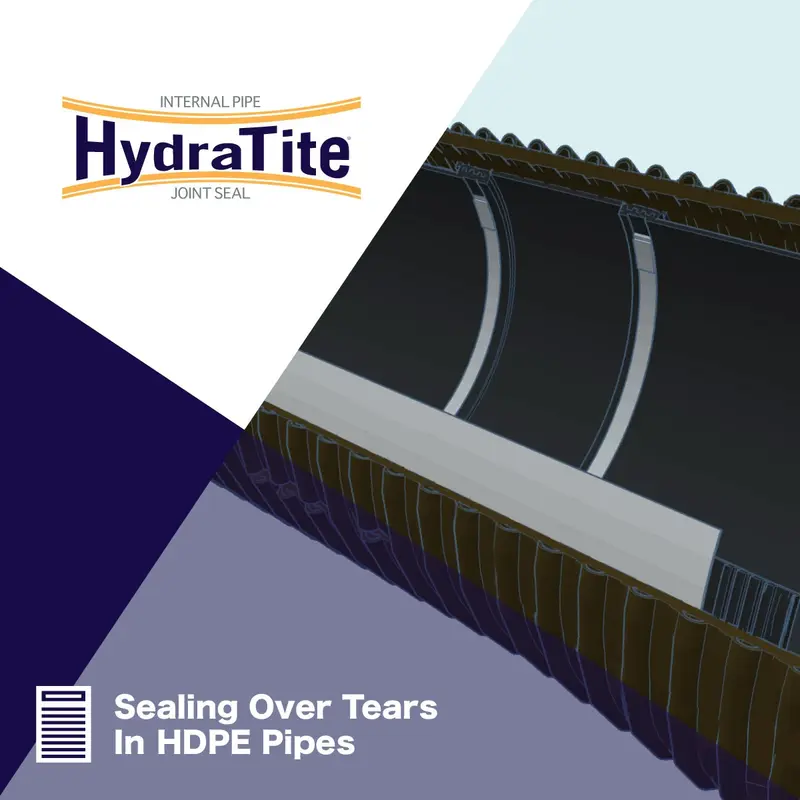

Large tears were discovered in HDPE storm pipes. HydraTite was installed in an interlocking sleeve over a backing plate to restore the integrity of the system.

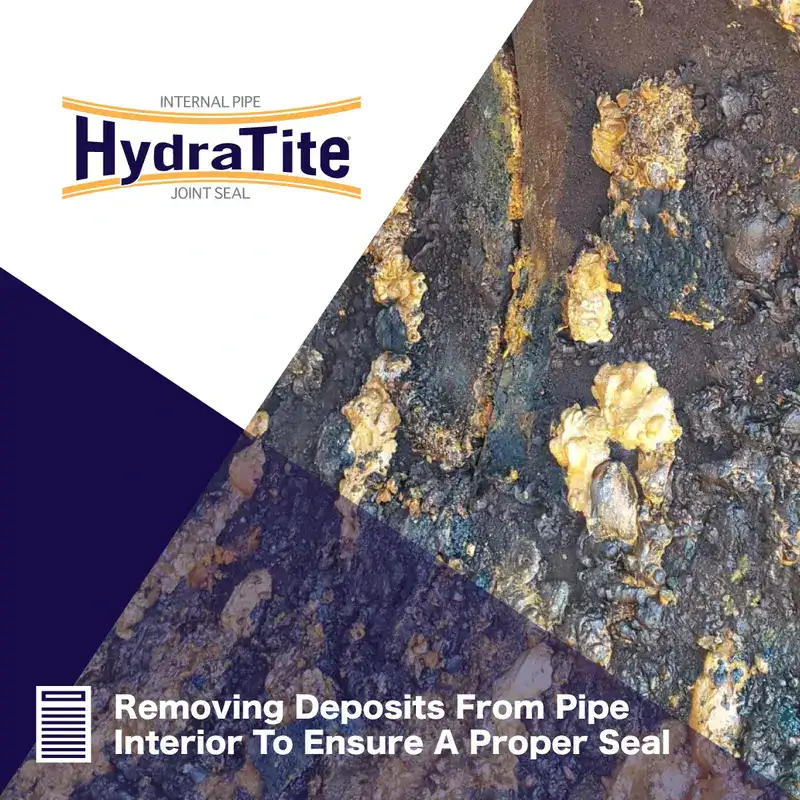

If the surface of the pipe is prepared for installation, most HydraTite seals can be installed in 45 minutes by a well-trained technician. Our field crew is very familiar with the seal, and this installation was completed in half that time. In only 20 minutes this joint’s leak was eliminated.

This 24″ pipe was rehabilitated in only two days with a crew of three people. One day to install HydraTite seals and another to apply HydraWrap.

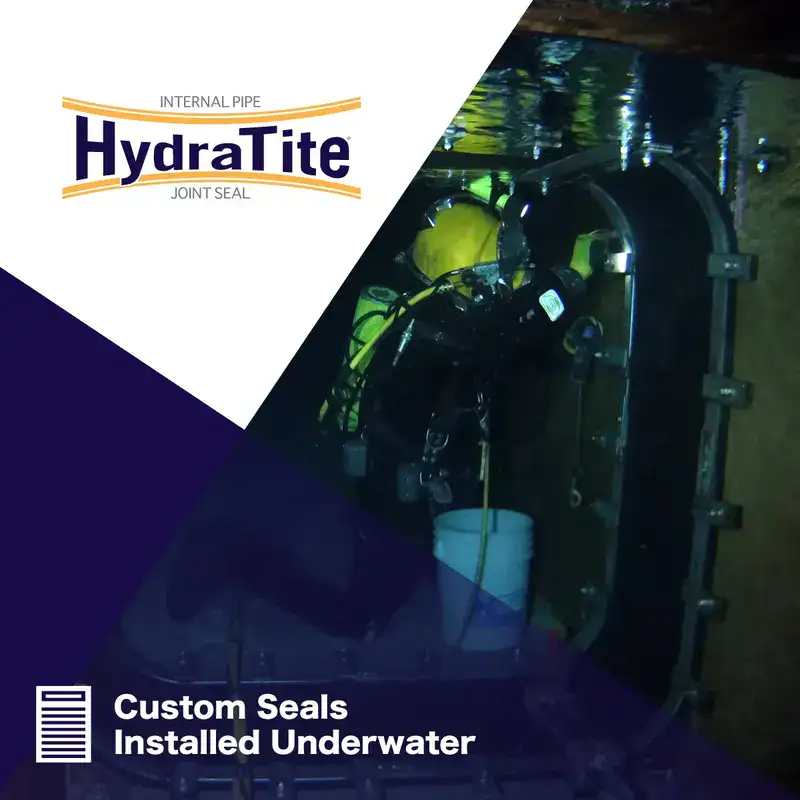

9 HydraTite seals were installed to eliminate leaks in this water treatment facility’s filtered water conduit system. The box seals were installed underwater by divers.

New housing was being developed in Georgia above stormwater pipes and the formation of sinkholes would be economically devastating. The developers wanted to guard against infiltration at several joints without digging down to the pipes.

A bulk water supply authority was faced with the challenge of repairing leaking joints at points in their network where open channels transition into pipes at river crossings. While the channels are concrete, the pipes are ductile iron and the expansion and contraction of dissimilar materials has been an ongoing source of leaks at the 2000mm diameter joints

We went to Texas was to provide a demonstration of our HydraTite Seal as well as show off our HydraLock seal to explain the capabilities and services we provide

In this month’s newsletter, Gen Z’s impact on the workplace is discussed. How will the employee-employer dynamics shift in the coming years?

Corrosion had resulted in wall loss for this copper nickel pipe that was part of a water cooling system on a Roll-on/roll-off (RORO) ship. Marine HydraWrap was chosen to repair this sysetm.

A steel mill became concerned with their stormwater pipeline. Testing the discharge at the end of the pipe revealed that contaminants had infiltrated the pipe through compromised joints. HydraTite was installed over the joints and eliminated the infiltration.

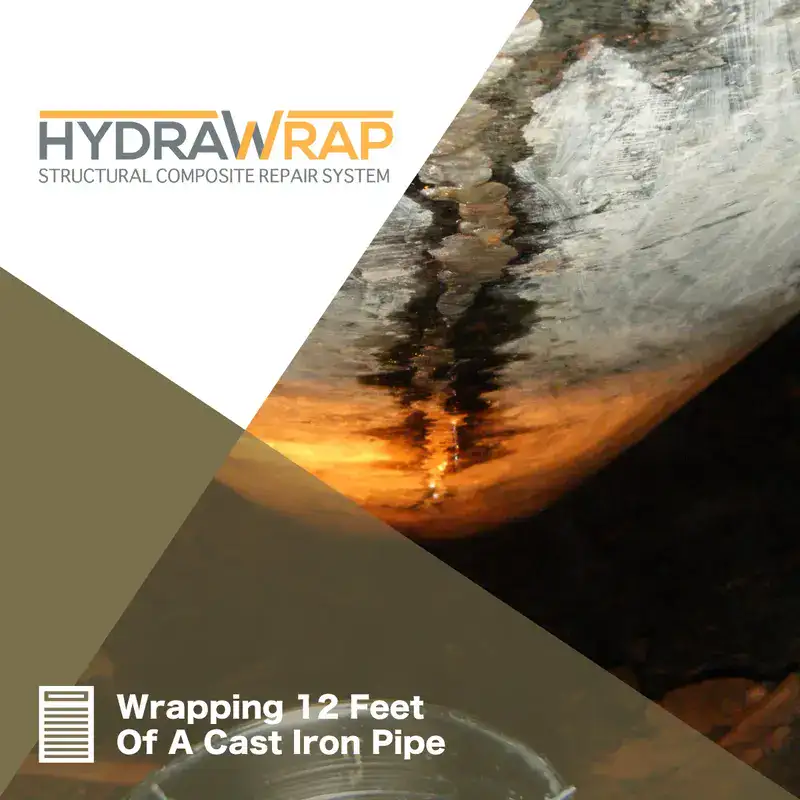

A 36” cast iron supply line pipe located in a tunnel had visible corrosion and an active leak. HydraWrap was applied to act as a protective layer against future corrosion and stop the leak.