Social Media Posts

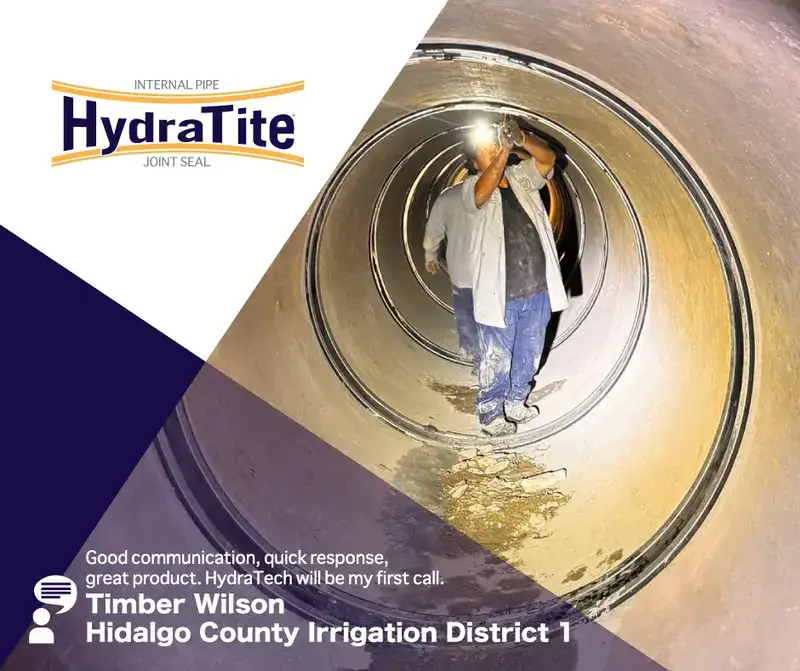

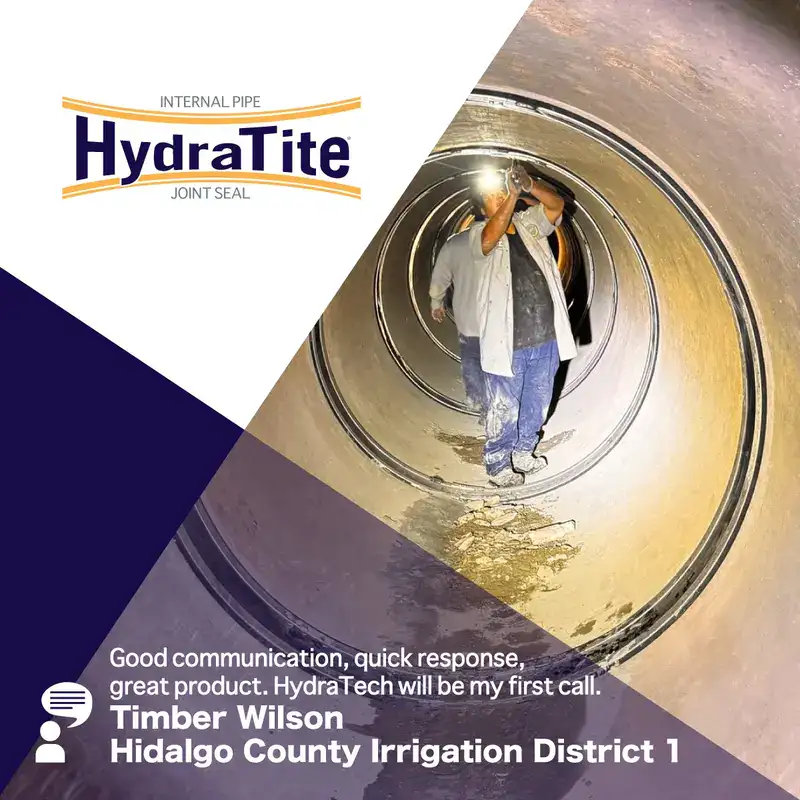

HydraTite was recently shipped down to Texas to seal 8 joints in a 72″ reinforced concrete pipe. Special thanks to Timber Wilson with the Hidalgo County Irrigation District, who took the time to give us this testimonial.

#HydraTite, #HydraTech, #PipingProfessionals, #DontReplacePiping, #RepairOverReplace, #PipeSeal

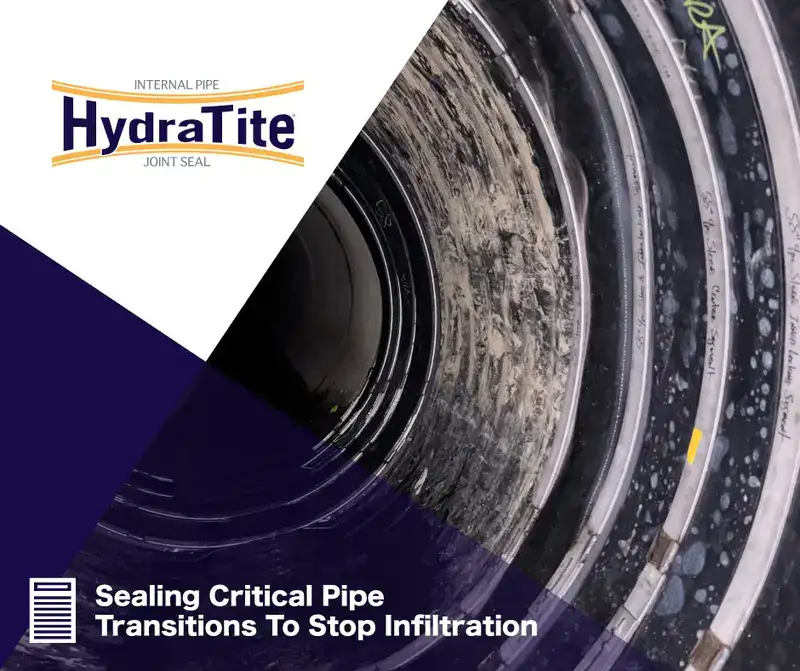

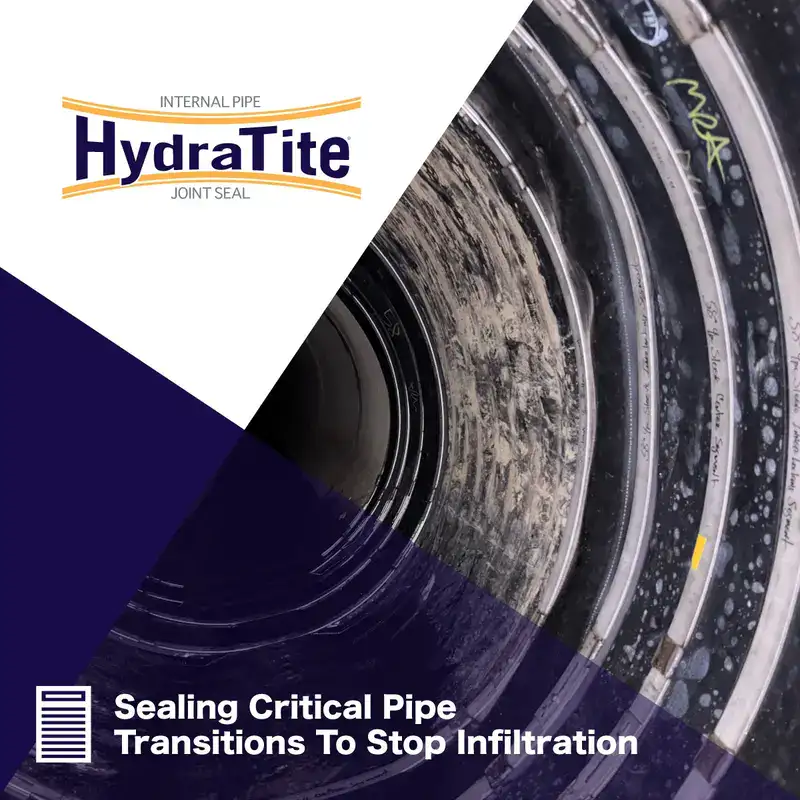

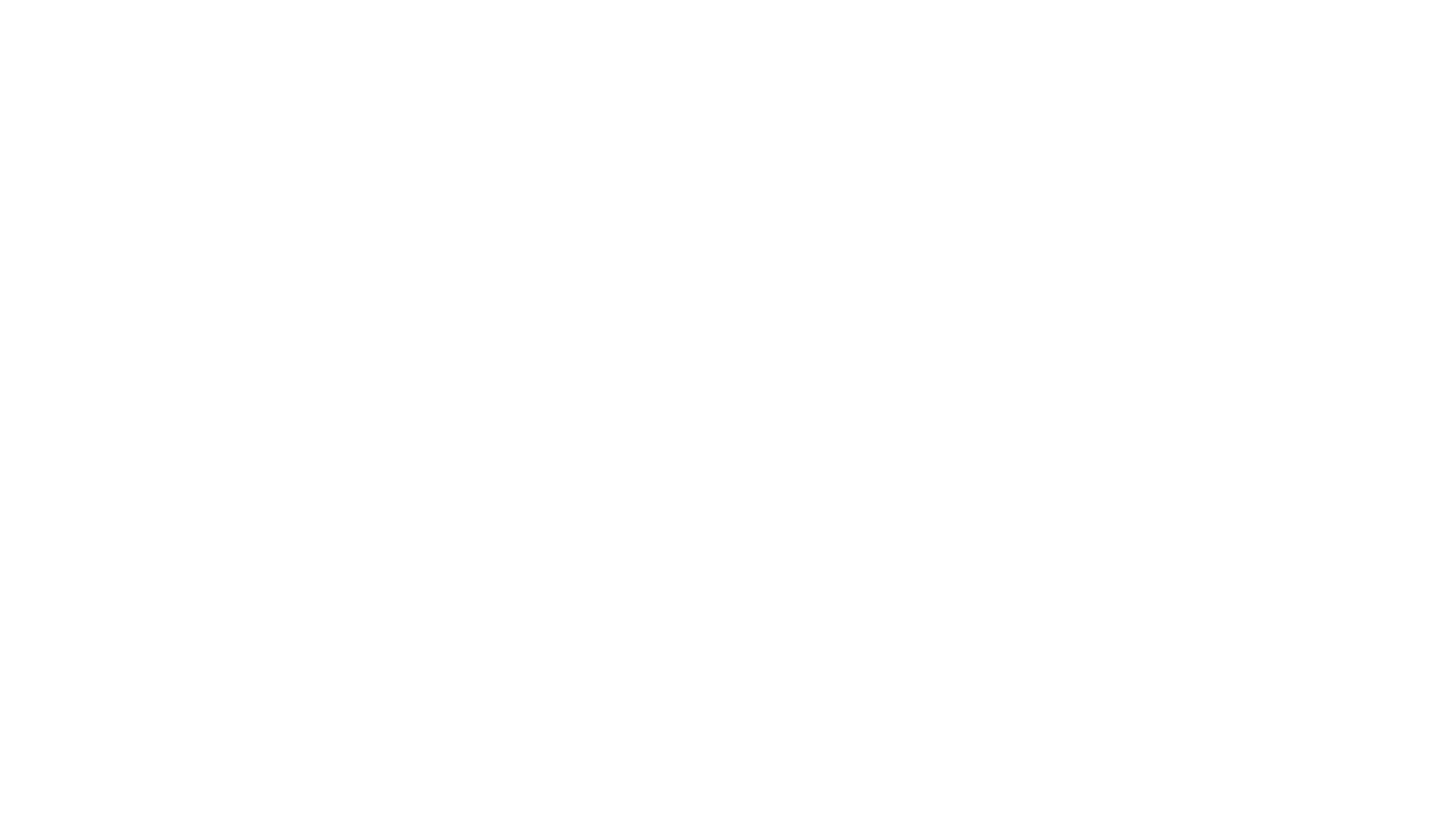

HydraTech manufactured and installed a custom-engineered HydraTite® Internal Pipe Joint Seal solution for an Ohio Department of Transportation stormwater pipe project. By using interlocking rubber sleeves with stainless steel retaining bands, filling corrugations with Pro-Stick®, and completing trenchless installation in just two days without excavation or traffic disruption, the repairs fully eliminated infiltration and restored watertight integrity to the critical joints.

#HydraTite, #HydraTech, #PipingProfessionals, #DontReplacePiping, #RepairOverReplace, #PipeSeal

It’s almost time! ⏳

WWETT 2026 is right around the corner, and HydraTech Engineered Products is gearing up for a great show.

📍 Booth 4068 — Indianapolis

Stop by to talk sealing solutions, infiltration prevention, and smarter infrastructure rehab. See you on the show floor!

HydraTech implemented the HydraTite® Internal Pipe Joint Seal system for the Ohio Department of Transportation to address infiltration at multiple compromised joints in a 48-inch corrugated metal pipe (CMP) and a 23-inch concrete pipe beneath a Cincinnati roadway, where soil/sediment entry caused pump station buildup and minor roadway sag due to failing liners, non-cylindrical joints, offsets, and other imperfections.

#HydraTite, #HydraTech, #PipingProfessionals, #DontReplacePiping, #RepairOverReplace, #PipeSeal

🚨 We’re Headed to WWETT 2026! 🚨

HydraTech Engineered Products is excited to announce that we’ll be exhibiting at the WWETT Show in Indianapolis — the premier event for wastewater and environmental service professionals across North America.

📍 Booth #4068

📅 February 17–19, 2026

📌 Indiana Convention Center

If you’re attending, make sure to stop by and see how our engineered sealing solutions are helping municipalities, contractors, and engineers extend infrastructure life, stop infiltration, and rehabilitate aging systems with confidence.

Whether you’re tackling leaking joints, planning rehabilitation, or exploring smarter long-term solutions — our team is ready to talk.

👉 Let’s connect at Booth 4068. See you in Indianapolis!

#WWETT2026 #Wastewater #Infrastructure #Trenchless #WaterInfrastructure #HydraTech #Rehabilitation #Municipal

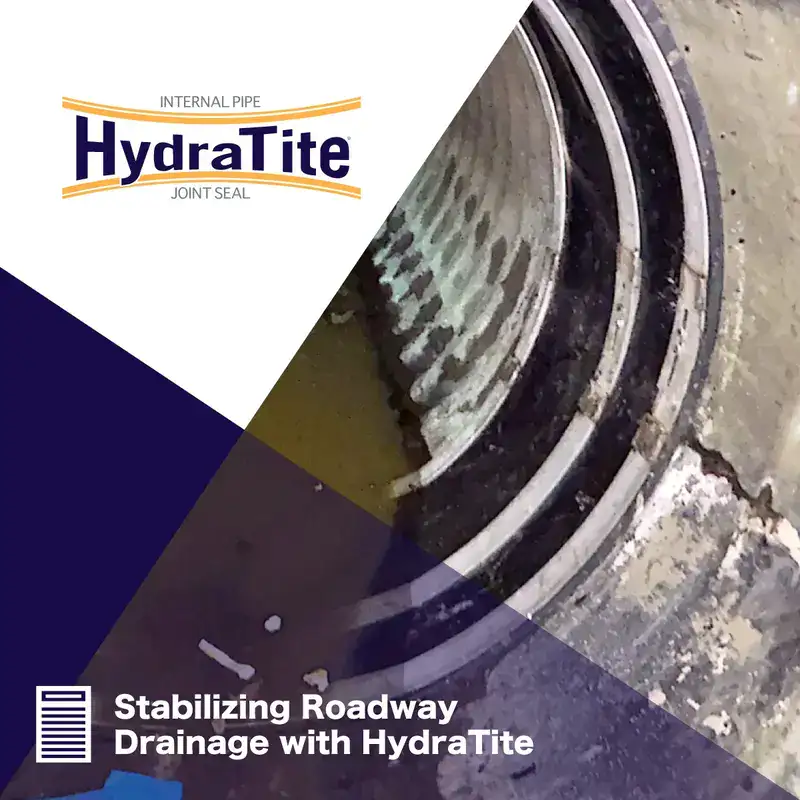

Two portions of a cooling water line onboard a ship were leaking. Limited access to this pipe made replacement an untenable solution. However, Marine HydraWrap proved to be the perfect solution to rehabilitate the pipe.

#CarbonFiberFix, #HydraWrap, #HydraTech, #ProtectProlong, #RepairOverReplace, #PipingProfessionals

Caleb recounted his experience at last year’s APWA in this blog post. HydraTech looks forward to this year’s show.

#HydraTite, #HydraTech, #PipingProfessionals, #HydraLock, #RepairOverReplace, #PipeSeal

Retention in infrastructure and maintenance fields is the direct result of leadership that respects employees, communicates clearly, provides growth opportunities, and treats employees as valued professionals.

#HydraTech, #PipingProfessionals, #HydraTite #PipeWork, #ThePipeline

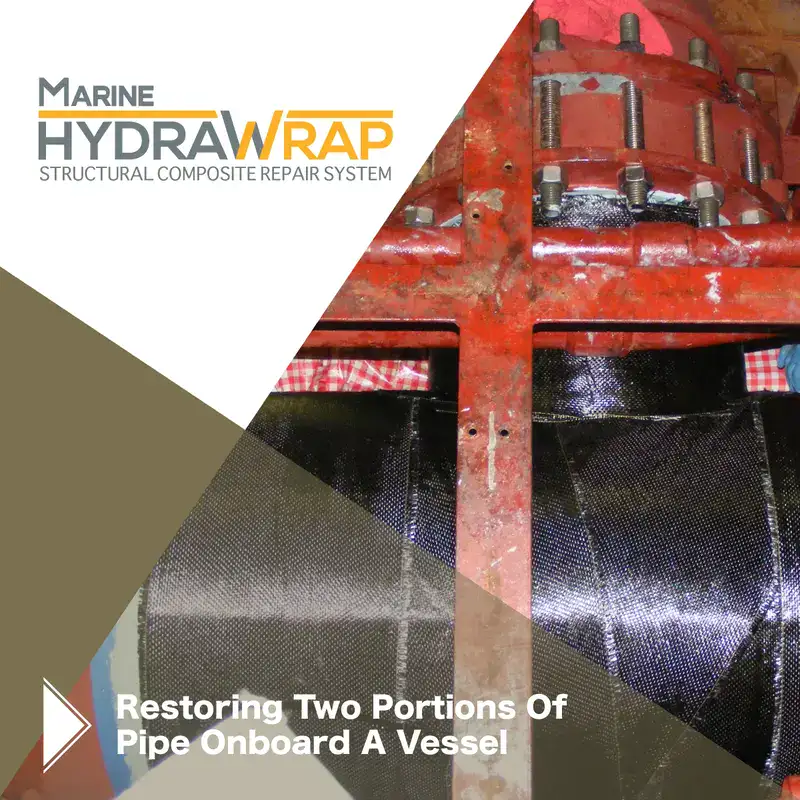

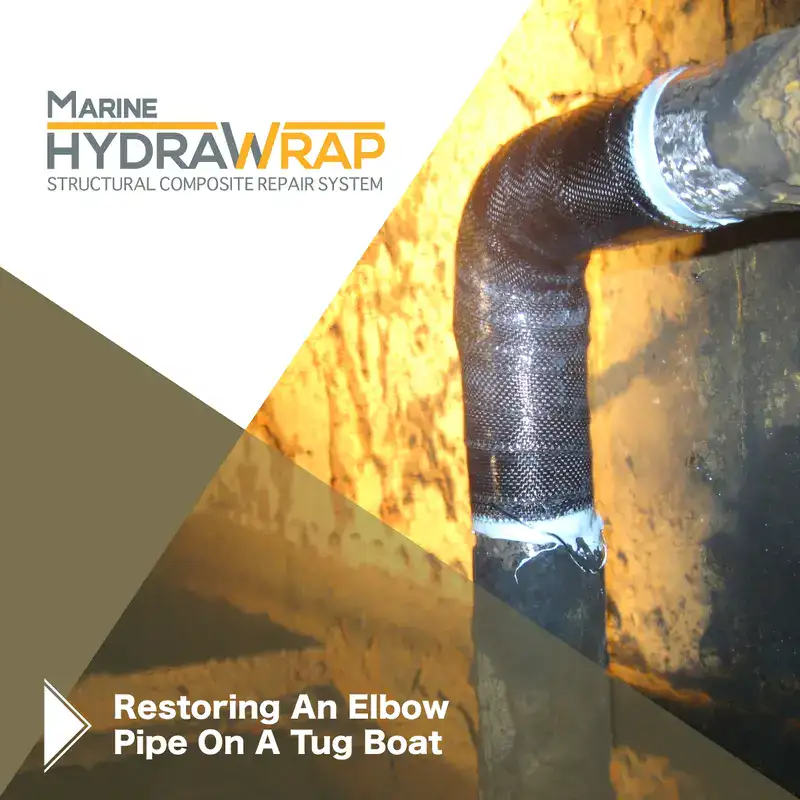

A leaking 4-inch elbow in a tugboat’s forward ballast tank suction line, caused by age-related deterioration, was efficiently repaired using the Marine HydraWrap Fiber Reinforced Polymer (FRP) system, avoiding labor-intensive replacement, hot work, or pipe removal and allowing the vessel to remain in operation.

#CarbonFiberFix, #HydraWrap, #HydraTech, #ProtectProlong, #RepairOverReplace, #PipingProfessionals

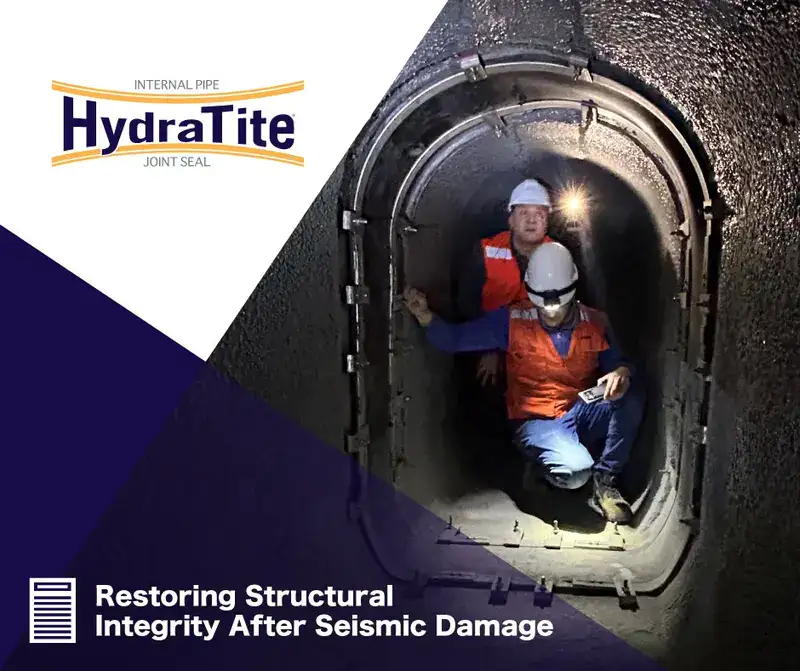

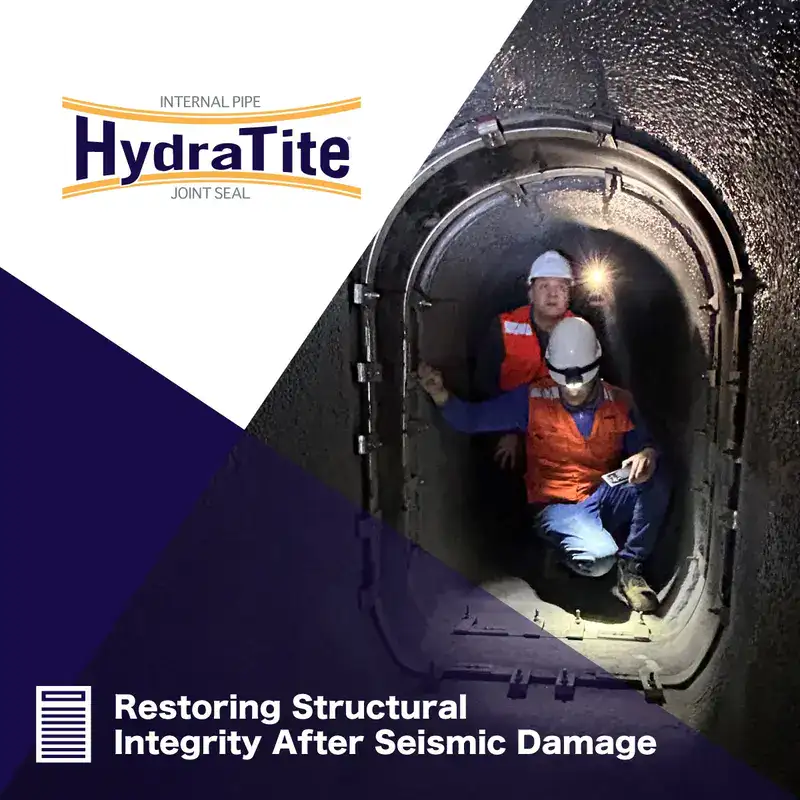

HydraTech delivered a customized HydraTite® Internal Pipe Joint Seal solution for a drinking water and irrigation system in Chile following the 2010 earthquake, which caused joint separations and persistent leakage in an 83 cm x 151 cm dual-arched aqueduct bridge despite failed external seals under 10 meters of water pressure and 3.6 m/s flow. The installation across 18 sections fully eliminated infiltration, restored structural watertight integrity, and proved effective for irregular, seismically damaged geometries without excavation.

#HydraTite, #HydraTech, #PipingProfessionals, #DontReplacePiping, #RepairOverReplace, #PipeSeal

HydaTite was recently used to seal joints fro the Hidalgo County Irrigation District. After the 72″ reinforced concrete pipe was sealed, Timber Wilson gave us positive feedback on his experince.

#HydraTite, #HydraTech, #PipingProfessionals, #DontReplacePiping, #RepairOverReplace, #PipeSeal

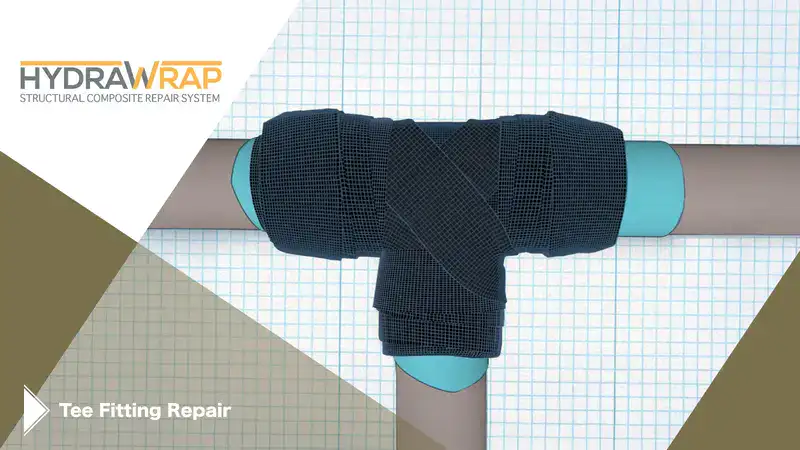

HydraWrap can be shipped in kits that include all the fabric and epoxy needed to repair a tee fitting. In this video, Caleb Rutledge goes step by step through the tee fitting repair. This highly customizable solution is quickly applied, durable, and simple to apply.

#CarbonFiberFix, #HydraWrap, #HydraTech, #ProtectProlong, #RepairOverReplace, #PipingProfessionals

While economic disruptions, layoffs, outsourcing, and technological change have eroded the traditional model of lifelong loyalty and steady career progression, careers persist as evolved, earned partnerships—especially in expertise-heavy fields like infrastructure—where employers must actively cultivate respect, mentorship, and meaningful development to retain talent, preserve institutional knowledge, and deliver reliable, high-quality outcomes.

#HydraTech, #PipingProfessionals, #HydraTite #PipeWork, #ThePipeline

Website Updates

The WWETT Show is always a cornerstone event for our industry, and this year’s gathering in Indianapolis was no exception.

🚨 We’re Headed to WWETT 2026! 🚨

HydraTech Engineered Products is excited to announce that we’ll be exhibiting at the WWETT Show in Indianapolis — the premier event for wastewater and environmental service professionals across North America.

HydraTech custom-manufactured HydraTite for this unique application in an arched aqueduct in a bridge system. Thomas Von Unger expressed his satisfaction with our seals in his recent testimonial.

HydraTite was recently shipped down to Texas to seal 8 joints in a 72″ reinforced concrete pipe. Special thanks to Timber Wilson with the Hidalgo County Irrigation District, who took the time to give us this testimonial.

HydraTech delivered a customized HydraTite® Internal Pipe Joint Seal solution for a drinking water and irrigation system in Chile following the 2010 earthquake, which caused joint separations and persistent leakage in an 83 cm x 151 cm dual-arched aqueduct bridge despite failed external seals under 10 meters of water pressure and 3.6 m/s flow. The installation across 18 sections fully eliminated infiltration, restored structural watertight integrity, and proved effective for irregular, seismically damaged geometries without excavation.

HydraTech implemented the HydraTite® Internal Pipe Joint Seal system for the Ohio Department of Transportation to address infiltration at multiple compromised joints in a 48-inch corrugated metal pipe (CMP) and a 23-inch concrete pipe beneath a Cincinnati roadway, where soil/sediment entry caused pump station buildup and minor roadway sag due to failing liners, non-cylindrical joints, offsets, and other imperfections.

HydraTech manufactured and installed a custom-engineered HydraTite® Internal Pipe Joint Seal solution for an Ohio Department of Transportation stormwater pipe project. By using interlocking rubber sleeves with stainless steel retaining bands, filling corrugations with Pro-Stick®, and completing trenchless installation in just two days without excavation or traffic disruption, the repairs fully eliminated infiltration and restored watertight integrity to the critical joints.

Careers aren’t disappearing, but they are no longer assumed; economic disruption and shifting expectations have reshaped how professionals evaluate long-term commitment. In infrastructure and trade-based industries, where expertise and institutional knowledge take years to build, workforce stability remains essential—and must now be earned through environments that respect experience, support growth, and sustain trust.

Games, food and fun at this year’s Christmas party. The Meritage was great as always, their food tasted awesome.

Marine HydraWrap proved to be the perfect solution for a vessel’s cooling water supply line that had begun leaking at it fittings downstream of the supply pumps.

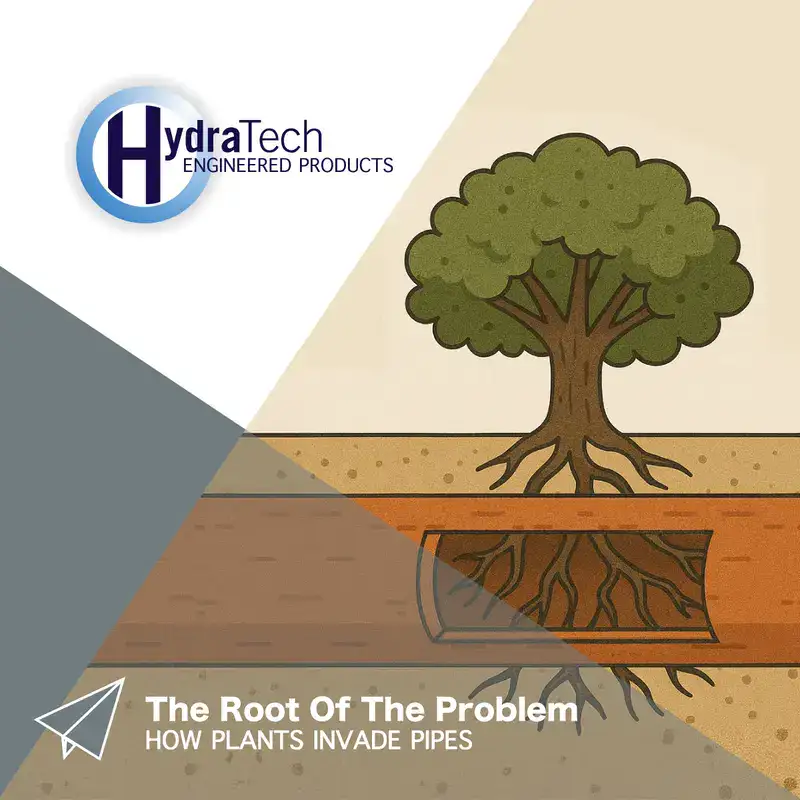

Tree root intrusion is a major cause of sewer and drain pipe blockages, with fast-growing, water-seeking species like willows, poplars, and maples exploiting cracks and joints in aging pipes. Preventing these costly failures requires a mix of smart landscaping, durable pipe materials or internal seals, chemical root inhibitors, and regular inspections to catch early signs of intrusion.

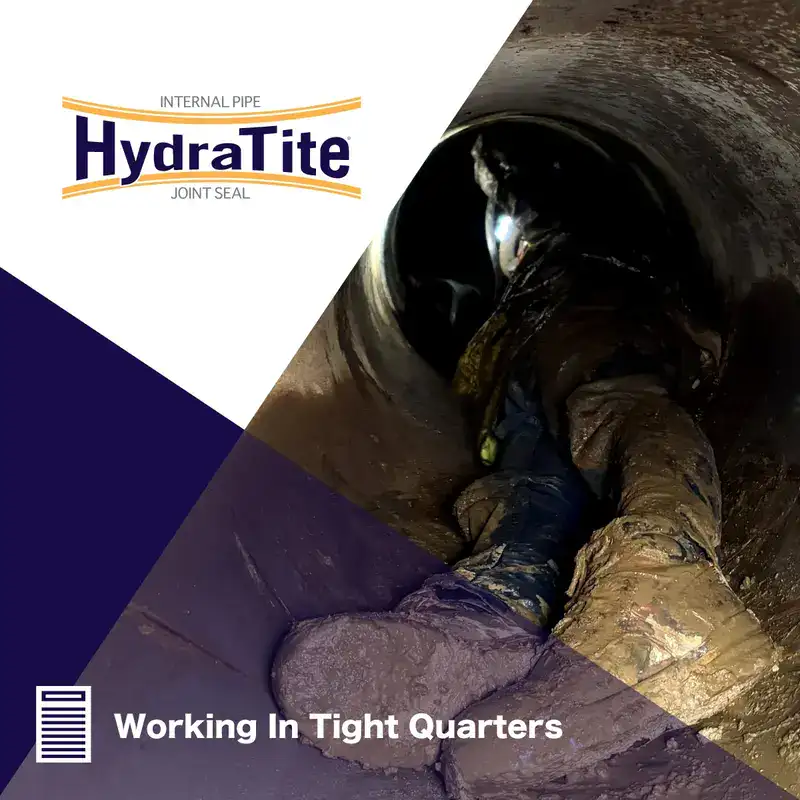

HydraTech was called to a New York water utility to repair a leak in a 24-inch ductile iron drinking water main connecting a pumphouse and elevated tower. Working within tight quarters, a two-person crew installed and air-tested two HydraTite® Internal Pipe Joint Seals in just one day, restoring the utility’s system.

By installing the seals internally, the team eliminated joint leakage and infiltration without the need for costly excavation or pipeline replacement in this aging water infrastructure for a municipality.