Box Seals Installed In A Coal Conveyor Tunnel

HydraTite® (Internal Joint Seal System)

Market

Power

Challenge

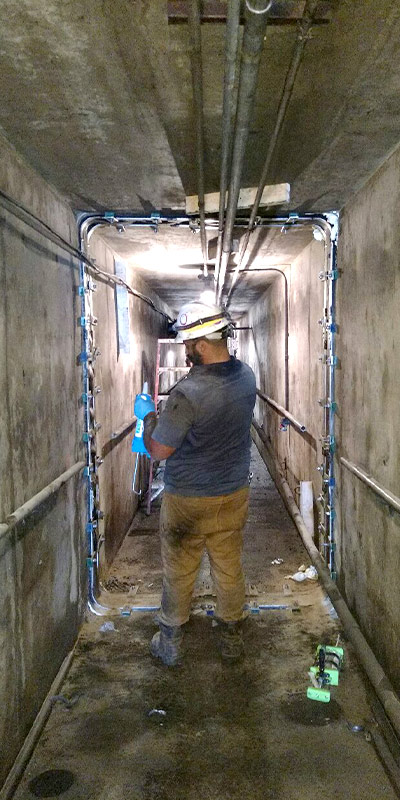

Groundwater was infiltrating a coal conveyor tunnel. The infiltration was at the joint of a concrete foundation in the tunnel. Damage from the water infiltration inside the tunnel was evident in the uneven settling of concrete sections. The water inside the tunnel also could damage equipment and was a slipping hazard for workers.

Engineered Solution

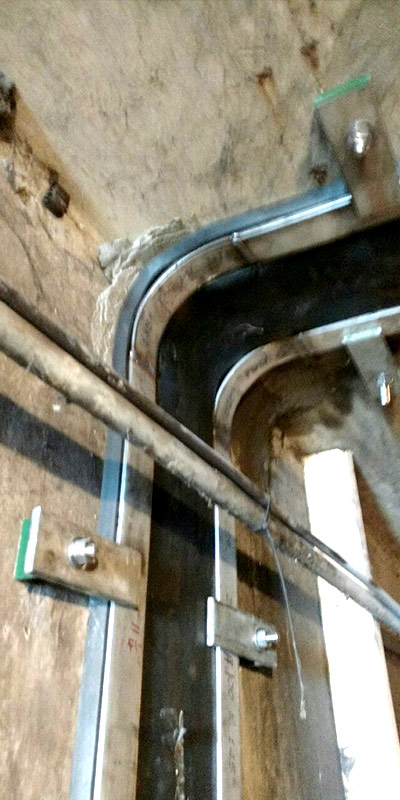

To eliminate the infiltration of water into the tunnel the HydraTite Box seal was proposed as a solution. The HydraTite Box seal is a customized mechanical remediation with no excavation required. The HydraTite Box seal flexibility accommodates ground settling and expansion/contraction. The seal’s superior quality and intricate design assure a tight and leak-free seal.

Scope

Surface prep included moving conduits, relocating beams for the conveyor system, and removing grout ports. The existing joint surface had to be chipped and scraped to create a clean surface for a watertight install. Due to the slope of the tunnel, concrete corners were used instead of steel forms to allow the HydraTite seal to accommodate the 90-degree corners. The straight sections of the HydraTite seal are equipped with anchor clips.

Solution

Once the surface prep was completed 5 box seals were installed. One seal was in an active conveyor tunnel and one was in an inactive conveyor tunnel the other 3 were in an access tunnel. The Box seal for the active tunnel was installed during an outage, as it was a critical work item. The job was completed in approximately 3 week and eliminated all infiltration.

Review the HydraTite Box Seal TDS.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature