Wrapping 12 Feet Of A Cast Iron Pipe

HydraWrap® (Fiber Reinforced Polymer)

Market

Municipal

Challenge

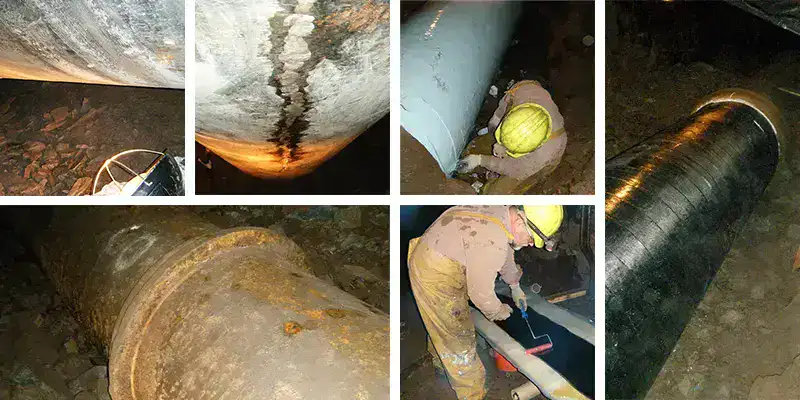

A 36” cast iron supply line pipe located in a tunnel had visible corrosion. A thru-wall defect was causing a 12-foot section between the bell and spigot to leak. A repair method was needed that could guard against corrosion as well as eliminate the leaking.

To eliminate the leak quickly and avoid costly replacement, a composite repair was chosen, 12” HydraWrap fabric with the standard epoxy.

Scope

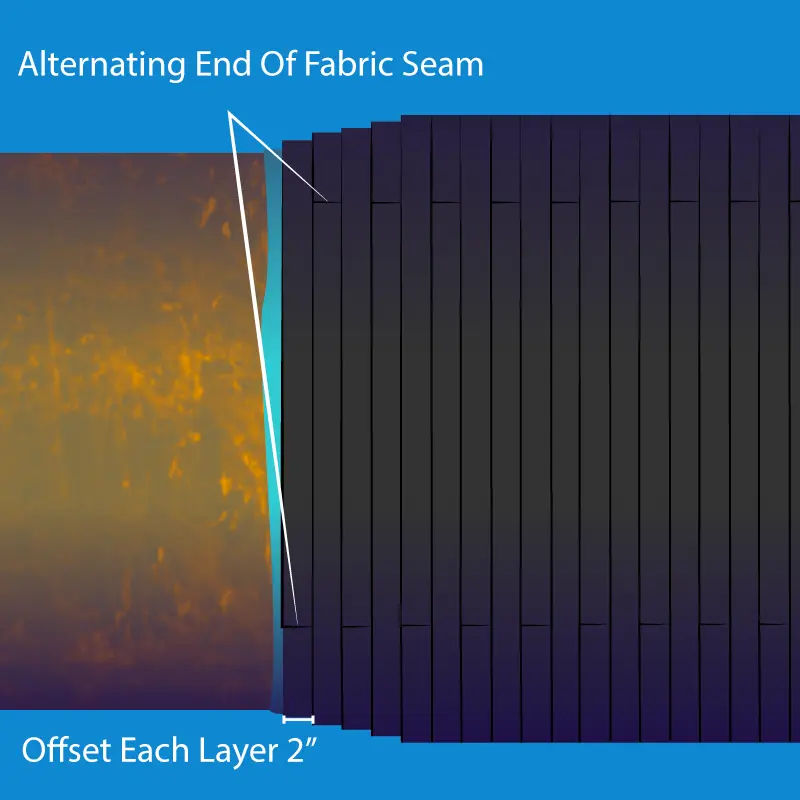

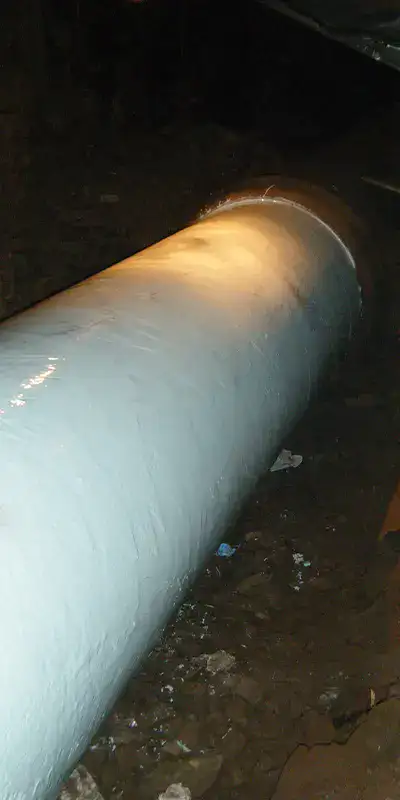

HydraWrap was applied in a weld repair fashion. A layer is applied, completely encircleing the pipe. Then the next wrap layer was offset 2” from the previous wrap. Each layer was applied the same way until all 12 feet were wrapped. The result was 5 layers of fabric over the repair area. Applying these 5 layers only took 2 days.

HydraWrap repaired the thru-wall leak and will provide a barrier against corrosion. This repair was completed at a fraction of the time and cost associated with replacement.

Explore HydraWrap

Explore HydraWrap

More Products

More Products

Case Studies

Case Studies

Explore HydraWrap

More Products

Case Studies

Explore HydraWrap

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature