Water Main Installation, Seven HydraTite Seals

HydraTite® (Internal Joint Seal System)

Market

Water & Utilities

Challenge

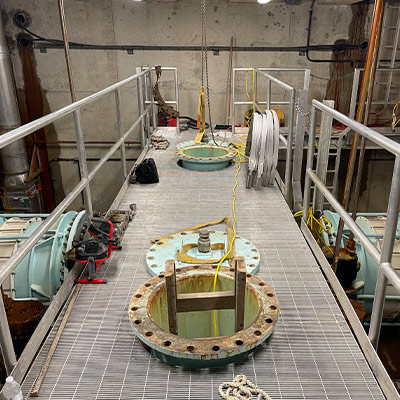

An aging 54” water main had begun leaking and raised concerns of sinkholes forming. The leaking pipes also threatened the potable water with contamination. Previous weld and grout repairs had failed to eliminate the leak. An installed liner covered most of the water main’s pipes, ending at two of the concerned joints. The liner decreased the diameter of the pipe on one side of these joints by approximately one inch compared to the host pipe.

Engineered Solution

The engineer searched for a solution that would not only eliminate leaks in this area but provide some flexibility as the liner had different thermal expansion for various water temperatures versus the host pipe. After some due diligence, the engineer selected the HydraTite Internal Joint Seal. HydraTite’s flexibility allows it to accommodate joints between pipes of different diameters, such as a pipe section with a liner and a section with just the host pipe.

Scope

Over the course of two days, seven extra-wide HydraTite seals were installed over the previous repair attempts. After each installation, the seals were individually air tested to ensure a watertight seal.

Solution

HydraTite proved to be an effective solution that eliminated the leak quickly and economically. This installation will help protect the facility from sinkholes and contamination for decades.

Related Content

HydraTite Internal Pipe Joint Seal, Air Test

HYDRATITE HIGHLIGHT

![]() 0:41

0:41

Water Main Installation, Seven HydraTite Seals

HYDRATITE CASE STUDY

![]() 1:34

1:34

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature