Sealing a High-Pressure Water Main Joint in Arkansas

HydraTite® (Internal Joint Seal System)

Market

Drinking Water

Challenge

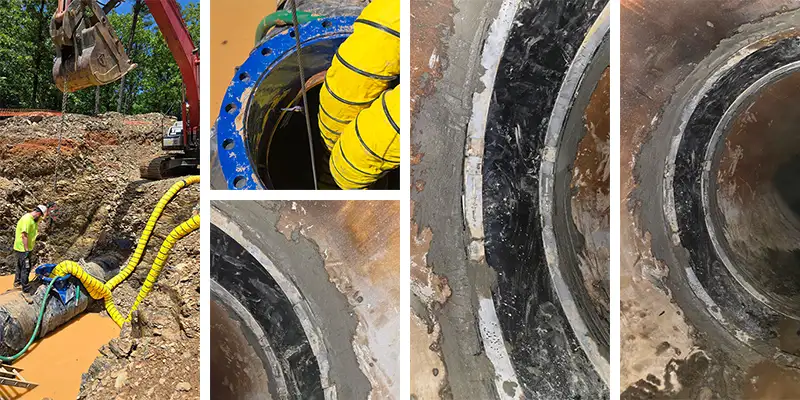

A municipal water utility in Central Arkansas discovered a failing joint in a 43.25-inch diameter metal pipe with a concrete liner. The joint, previously welded, had separated under operational pressure, causing exfiltration and pressure loss. The leak risked further pipeline degradation, necessitating an immediate, durable repair without costly excavation or replacement.

Engineered Solution

HydraTech’s extra-wide HydraTite Internal Pipe Joint Seal was selected to restore the joint’s integrity. This trenchless solution provides a robust, pressure-resistant seal, eliminating the need for full pipe replacement while ensuring long-term protection, despite under high-pressure conditions.

Scope

The project required sealing one compromised joint in a 43.25-inch water main. After ventilation was established, two HydraTech technicians were lowered into the pipe via a winch connected to an excavator. They chipped away the concrete liner to expose the metal pipe, cleaned the surface, and installed the HydraTite seal by positioning the rubber over the joint, securing it with retaining bands, and locking them in place. An air test verified the seal’s integrity, and concrete was applied to restore the liner. The repair took three hours, and once the concrete hardened, the pipe resumed service, maintaining pressure.

Solution

The HydraTite seal prevented costly excavation and restored operations quickly. The joint will be safeguarded against destructive leaks for many years to come.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature