Repairing Two Tee Fittings

HydraWrap® (Fiber Reinforced Polymer)

Market

Marine

Challenge

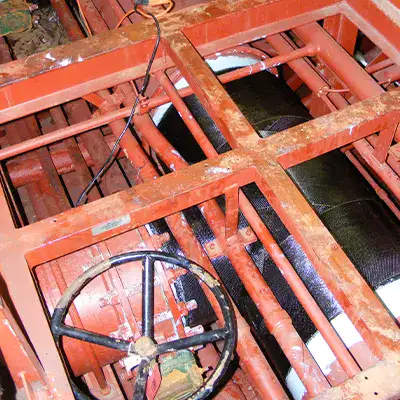

Corrosion had resulted in wall loss for this copper nickel pipe that was part of a water cooling system on a Roll-on/roll-off (RORO) ship. The damage was localized to two tee fittings in which an 18” pipe terminated into a 24” pipe. Replacement-in-kind would be costly and a repair that reinforces the weakened portion of the pipe would be quicker. This project required an ABS Design Approved repair.

Engineered Solution

Marine HydraWrap® Structural Composite Repair System, an ABS Design Approved technology, was chosen to give new strength to this compromised portion of the pipe.

Scope

On a previous project, HydraTech had trained the vessel’s personnel and now they were prepared to apply this repair themselves. First, the surface had to be ground clean to ensure a proper mechanical profile could be achieved. Epoxy was then applied to the repair area. 12” carbon fiber fabric was applied in 4 layers. In roughly a day both tee fittings were strengthened and fortified against future corrosion.

Solution

The vessel personnel picked up the application fast as it is a straightforward process and they were able to apply what they learned right away. Marine HydraWrap provided a quick solution to a serious problem at a fraction of the cost of replacement.

Sister Project

Explore Marine HydraWrap

Explore Marine HydraWrap

More Products

More Products

Case Studies

Case Studies

Explore Marine HydraWrap

More Products

Case Studies

Explore Marine HydraWrap

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature