HYDRAWRAP INSTALLATION DEMO

Office Workers Get a Taste of the Field

![]() Caleb Rutledge, 8/28/2020

Caleb Rutledge, 8/28/2020

HydraTech Engineered Products employees stepped out of their comfort zone last Friday. They put down their phones and files to pick up a brush and fiberglass to learn how HydraWrap is applied to a concrete pipe. Mike Fox, the company engineer, took some time to instruct Heather Spurlino, Caleb Rutledge, and Jennifer Williams on this technology.

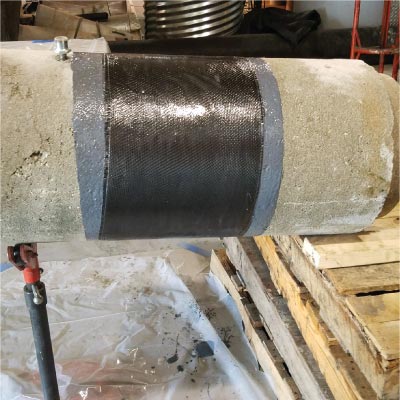

The Elevated Temperature HydraWrap Kit was selected for the demo. This kit is designed for a continuous service temperature of 215 F. Heather used a drill to mix the primer until the marbling was completely gone. First, the pipe was cleaned of debris and scaling. Next, the section of the pipe the HydraWrap system was to be applied to was marked with painting tape and the primer was brushed on by Caleb and Heather. The primer was checked to ensure it thoroughly coated the pipe.

Once the pipe was covered in primer the fiber wrap was laid out on a table and the epoxy was mixed thoroughly. Wedges were used to work the epoxy into the fibers. The wrap was flipped and then the process was duplicated on the other side. This is referred to as the wet-out process. The first layer was slowly wrapped around the pipe to make sure that the fiber wrap was tight and was not bunched or folded. Another length was laid out on the table, wetted, and then applied.

Jennifer watched and documented the whole process that took just a bit more than an hour. The technology proved to be easy enough to install for our office crew. Heather, Caleb, and Jennifer got an up-close look of this product, ensuring they are all ready to explain how it works and its capacity to rehabilitate pipe to our interested customers. Through this experience, they learned that the number of layers could vary based on the needs of the project and that two layers are the minimum. They learned that the product has a bidirectional fiber composition that sets it apart from other similar products. This allows HydraWrap to strengthen infrastructure against stresses from multiple directions. To learn more about the advantages of the HydraWrap, Click Here.

“Soon after I was hired to work in the front office, I was walked through the HydraTite Seal’s installation. Watching the product be applied brought to life the brochures I had read, and it helped when people would call in with questions about the seal. Getting to see how HydraWrap works will help in the same way. Plus it was a nice change of pace from the day to day office work.”