9 Common Reasons Pipes Fail

Caleb Rutledge 11/29/2023

Caleb Rutledge 11/29/2023

Time wears away at all infrastructure and while pipes may be out of sight, the results of pipe failure can be very visible. Near us in Cincinnati, a water main failure resulted in a car falling into a large sinkhole that formed. Catastrophic events like this are likely to become more common due to the fact that the average age of our water and sewer pipes is about 45 years (↳Tommy Stricklin). “Aging” may be a common link between many pipe failures, but what are the contributing factors? What initiates the small defect that allows infiltration and exfiltration to exacerbate the problem?

- Pressure Changes

- Temperature Fluctuations

- Movement

- Defective Installation

- Invading Roots

- Excavating Accidents

- Internal Build-Up

- Sun Exposure

- Corrosion

Knowing which of your pipes are most susceptible to is crucial in prevention and early detection.

Pressure Changes

Perhaps the pressure has increased and while the pipe may be rated for the higher pressure, the fittings, joints, valves, and welds may not be as durable. Besides just a simple pressure increase, pipe failure may also be attributed to what is known as water hammering (↳Supreme Steel Pipe Corp). This happens when a valve is abruptly shut bringing the water to a halt sending a shockwave down the pipe that has a sound resembling hammering. This can slowly degrade your pipe.

Higher pressure problems can be resolved by lowering the pressure, clearing out debris inside the pipe, or upgrading the pipe and fittings. Water hammering is frequently considered in the installation of pipes through the inclusion of air chambers that compress when hit with this shockwave. These can become waterlogged and as a result, cease to provide protection to the pipe. Refilling these chambers with air is the solution, and on the small side of piping this may look like shutting off your house’s water and letting the faucets drain (↳Fix-It Club). Also, some pipes handle water hammering better than others. for instance, high-density polyethylene pipes(HDPE) are 2,500 times more resistant to damage from water hammering than polyvinyl chloride pipes(PVC) (↳WL Plastics).

Temperature Fluctuations

Pipe material varies in effectiveness as the temperature is lowered or raised. Freezing temperatures result in pipes busting due to cold water increasing its volume by approximately 9% when it freezes(↳IAPWS). This, in turn, interferes with the water supply for a quarter million homes in the United States every year (↳Chip). Freezing can also damage a pipe slowly over time. Water can fill small cracks in concrete culverts and expand during the winters, year by year allowing the spalling and pitting to progress. On the other side of the coin, heat presents a bigger threat to certain pipes such as PVC.

Depending on the surrounding environment and the expected temperatures, one pipe material may be more appropriate than another for installation. Cross-linked polyethylene pipe (PEX) is more resistant to cold temperatures than copper or PVC (↳Chip). However, copper would better suit a hot environment than PEX. Pipe insulation can help mitigate the surrounding temperature’s effect. Increasing flow and pressure can help deter freezing. Resurfacing concrete culverts to minimize imperfections can limit damage from freezing.

Movement

Many pipelines are designed to be stationary and are not very tolerant of movement. The most obvious movement that could damage pipes is that from earthquakes. Man-made shifting of the soil can be caused by large construction above ground as well. The soil can also shift slowly over time. An example of this would be soil creep, the downward progression of rocks and soil. While not directly visible this is very apparent in the way trees grow, as depicted above (↳Max). Cast iron pipes don’t handle the stress of an earthquake well and frequently fail at their brittle joints. Ductile iron pipes are less likely to fail in the same way but rather are more likely to become separated at the joints during the shifting. Shifting internal pressures can also move the pipe, especially if it is above ground.

“Pipes that are rugged, resist bending damage, have joint flexibility, and are either continuous or have restrained joints are less vulnerable” (↳Donald Ballantyne) HDPE and molecularly oriented PVC (PVCO) both handle movement better than PVC (↳Donald Ballantyne). Pipes that are above ground should be properly anchored to restrict movement (↳Carrie).

Defective Installation

Pipes being installed incorrectly, or not pipes not suited for the location or purpose can result in pipe failure. Your pipe may be the best material for the application, but if the connection points are not correctly together, the system will fail. Ensuring that your installer is a professional and making sure they are aware of all the strains the system will be under is very important. HydraTech has been tasked with sealing leaks with HydraTite in pipes that developed leaks immediately after they were installed.

Invading Roots

Root growth can indirectly affect a pipeline by creating pressure or directly affect the pipe by working its way in through small pipe defects or joints, making the entry point larger and larger over time. Already leaking pipes can entice roots to worsen the problem (↳The Morton Arboretum). If roots enter your pipe they can restrict flow and increase pressure as well.

Pipes can be protected with liners and/or barriers. Root-resistant PVC can be installed. Plant life can be removed or cut back prior to installation (↳IT Landes Home). Chemicals can be used to kill roots but the permeant solution is ultimately replacement (↳The Morton Arboretum).

Excavating Accidents

Underground cables and pipes are damaged by unrelated construction all the time. In the USA these lines were unintentionally struck 340,000 times in 2014. Depending on the purpose of the line, the results can be deadly (↳Radiodetection).

The only solution is better awareness of what is below when digging. This can be accomplished by calling 811 to have the state mark the utilities prior to a project (↳811). Give extra space to where the utilities are believed to be. You can also reference utility maps and make use of detection tools that use electromagnetic signals to find the utilities (↳Ridgid).

Internal Build-Up

Many different things can build up in your pipe and some build-ups are more common in certain situations. Pipes that carry hard water frequently develop calcium build-up (↳Village Plumbing). Tuberculation is common in older iron drinking pipes (↳Trenchlesspedia). Biofilms, and microbial communities, can restrict flow in smaller pipes and speed up corrosion in metal pipes (↳Jaya Rawat & Others). Fatbergs, masses formed from non-degradable materials and fatty substances, are commonly found in urban sewer systems and an 820-foot fatberg was discovered in London (↳Anna Schaverien). Discarded plant life can also build up. On a recent project, rotting corn stalks had become lodged at one end of a culvert.

Picking the best pipe material for the situation is key. Remember how HDPE Pipe handles water hammering better than PVC? Well, biofilms present a bigger problem for HDPE than PVC (↳NIH). Filters can be installed and cleaned regularly. Epoxies can be used to coat pipes that tend to form tuberculation. Man-entry-sized pipes can be cleared by hand, as was done in the previously mentioned job with the corn stalks. Chemical agents can sometimes be used to break down build-ups, such as when backing soda, a base, is used to break down biofilms in home plumbing(↳Diamondback).

Sun Exposure

Plastic-based pipes are more susceptible to degradation from Ultraviolet Radiation (UV) than metal pipes. However, many of these metal pipes have protective coatings to help prevent corrosion. These coatings can be broken down by UV (↳Phil McKenna). Many of these pipes are intended to be underground and avoid the sun but are left above ground for an extended period due to delays and shifting construction schedules. After installation, the damage that is already done may become apparent.

Selecting the correct pipe designed for UV exposure is crucial and if pipes are not intended to be in the sunlight, keep them out of the light by covering or coating them.

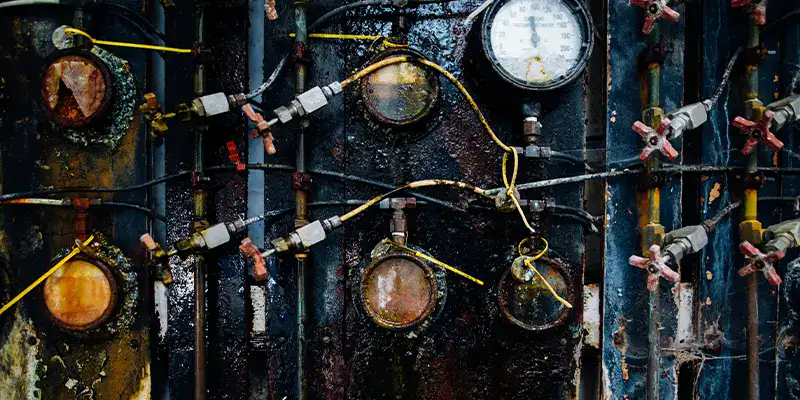

Corrosion

Oxygen sources such as air and water both contribute to the oxidizing process known as corrosion. Acidic soils and drain cleaners can also function as accelerants. Protective coatings can slow the limit the corrosion process, but as noted previously, these can be broken down. Plastic-based pipes such as PVC do not react to water and air in the same way and therefore do not rust or corrode in the traditional sense (↳Think Pipes). Biological corrosion is the result of microorganisms in the water and this can affect more materials than just metal (↳Trenchlesspedia).

Choosing pipes manufactured from stainless steel or aluminum would be a good option as they are not prone to corroding. Maintaining and cleaning your pipes can cut down on biological corrosion. Ensuring that the water does not remain stagnant in the pipes can help minimize biological corrosion. Finally, some chemical agents are used to fight biological corrosion as well.

Sources

Ballantyne, Donald, and Ballantyne Consulting LLC. Overview of Piping Systems and Their Seismic Vulnerability, www.responsiblechoice.info/wp-content/uploads/Overview-of-Piping-Systems-and-their-Seismic-Vulnerability.pdf. Accessed 22 Nov. 2023.

“Biological Corrosion.” Trenchlesspedia, 5 July 2023, www.trenchlesspedia.com/definition/2706/biological-corrosion.

Blog-manager. “5 Causes of Pipe Failure.” Supreme, 21 Jan. 2021, supremepipe.com/blog/causes-pipe-failure/.

Brethauer, Alexis. “9 Ways to Avoid Tree Roots in Your Pipes.” IT Landes, 8 May 2023, itlandes.com/9-ways-to-avoid-tree-roots-in-your-pipes/#:~:text=Install%20PVC%20Pipes,their%20durability%20and%20long%20lifespan.

Carrie. “What Is a Pipe Anchor?” Making Pipe Supports Easy to Deal with Since 1991, www.appmfg.com/blog/what-is-a-pipe-anchor. Accessed 22 Nov. 2023.

Chip. “How to Tell Which Pipe Material Is Best during Winter – Make It Mowery.” Make It Mowery – Make It Mowery, 6 Dec. 2022, makeitmowery.com/how-to-tell-which-pipe-material-is-best-during-winter/.

Club, Fix-It. “How to Fix Pipes.” HowStuffWorks, HowStuffWorks, 1 Jan. 1970, home.howstuffworks.com/home-improvement/plumbing/how-to-fix-pipes5.htm.

FAQ: Water Expansion on Freezing, www.iapws.org/faq1/freeze.html. Accessed 22 Nov. 2023.

“For Homeowners.” Call 811, call811.com/Start-Here/Homeowners#:~:text=Notify%20utilities%20of%20your%20intent,property%20with%20paint%20or%20flags. Accessed 22 Nov. 2023.

Gbadmin. “The Problem with Biofilm and How to Avoid It.” Diamondback Plumbing & Cooling, 11 Apr. 2023, www.diamondbackplumbing.com/blog/the-problem-with-biofilm-and-how-to-avoid-it/.

“Home.” Think Pipes. Think PVC, www.thinkpipesthinkpvc.com.au/benefits-of-pvc-pipes/corrosion-resistance#:~:text=Unlike%20metal%20piping%2C%20PVC%20Pipes,longer%20lifetime%20of%20the%20pipe. Accessed 22 Nov. 2023.

Langston, Dustin. “HDPE vs. PVC Pipes.” WL Plastics, 24 Apr. 2023, wlplastics.com/hdpe-vs-pvc-pipes/#:~:text=Compared%20to%20PVC%2C%20HDPE%20is,cracking%20and%20failure%20over%20time.

Max. “Kann Eine DNA Analyse Der Dürreresistenz in Buchen Ihre Zukunft Sichern?” Multiperspektivischer Blick Auf Die Biodiversität Im Wald, 17 Nov. 2021, biodiv-im-wald.online/kann-eine-dna-analyse-der-duerreresistenz-in-buchen-ire-zukunft-sichern.

McKenna, Phil. “Too Much Sun Degrades Coatings That Keep Pipes from Corroding, Risking Leaks, Spills and Explosions.” Inside Climate News, 7 Dec. 2020, insideclimatenews.org/news/11102020/pipeline-coating-keystone-xl/.

plumbing, Village. “What Causes Calcium Build up in Pipes?: Village Plumbing.” Village Plumbing and Air, 4 July 2023, villageplumbing.com/blog/what-causes-calcium-build-up-in-pipes/.

RAWAT, JAYA, et al. Microbiological Causes of Corrosion, Bharat Petroleum Corporate R&D Center, www.digitalrefining.com/article/1000999/microbiological-causes-of-corrosion#:~:text=Biofilm%20influences%20the%20physic%2Dchemical,values%2C%20and%20oxidation%20reduction%20potential. Accessed 22 Nov. 2023.

“Reducing Damage to Underground Pipes and Cables.” Radiodetection, www.radiodetection.com/en/reducing-damage-underground-pipes-and-cables. Accessed 22 Nov. 2023.

Rożej, Agnieszka, et al. “Structure and Microbial Diversity of Biofilms on Different Pipe Materials of a Model Drinking Water Distribution Systems.” World Journal of Microbiology & Biotechnology, U.S. National Library of Medicine, Jan. 2015, www.ncbi.nlm.nih.gov/pmc/articles/PMC4282696/.

“SeekTech SR-24 Support.” SeeSnake, support.seesnake.com/sr-24/. Accessed 22 Nov. 2023.

Schaverien, Anna. “Scientists Solve a Puzzle: What’s Really in a Fatberg.” The New York Times, The New York Times, 4 Oct. 2019, www.nytimes.com/2019/10/04/world/europe/sidmouth-fatberg.html.

Stricklin, Tommy. “America’s Aging Water Pipes: Is Your Tap Water at Risk?” SpringWell Water Filtration Systems, 11 Oct. 2023, www.springwellwater.com/americas-aging-water-pipes-risk/.

“Tree Root Problems: Girdling Roots, Pipes, Severing.” The Morton Arboretum, 24 Mar. 2023, mortonarb.org/plant-and-protect/tree-plant-care/plant-care-resources/tree-root-problems/#:~:text=As%20roots%20enlarge%2C%20they%20may,the%20break%20in%20the%20pipe.

“Tuberculation.” Trenchlesspedia, 31 Oct. 2023, www.trenchlesspedia.com/definition/3419/tuberculation.