Restoring Two Vertical Digester Pipes

HydraWrap® (Fiber Reinforced Polymer)

Market

Wastewater

Challenge

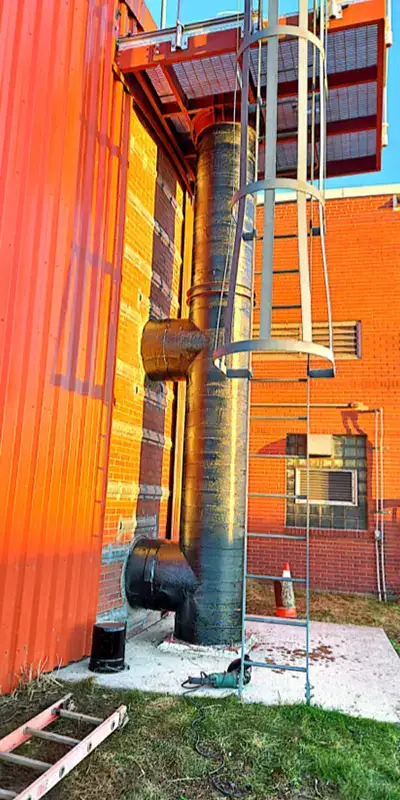

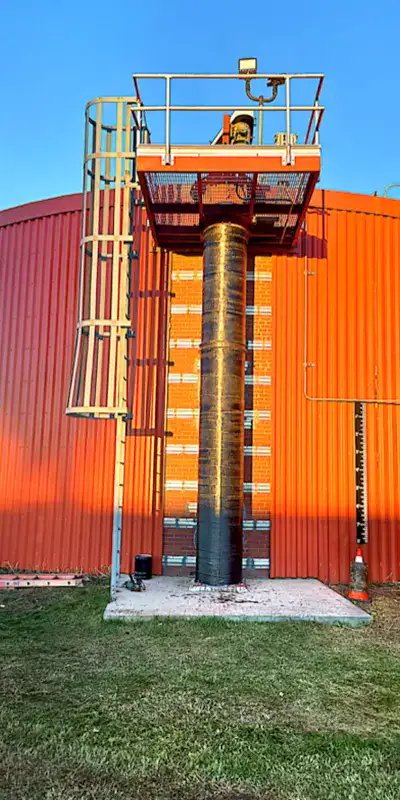

Corrosion was visible at the base of two carbon steel vertical digester mixing pipes. This corrosion had compromised the system and it had begun leaking. As a temporary measure, epoxy was used to stop the leak but the wastewater facility needed a permanent repair that could be applied without putting the system out of service.

Engineered Solution

HydraWrap was the chosen solution. 12” carbon fiber fabric was to be used with standard epoxy.

Scope

Scaffolding was set up so that technicians could access the entire 18-foot section of pipe that needed to be repaired. Because of corrosion there was expected wall loss to this pipe, which was only 0.4” thick to begin with. Therefore, special care was taken to avoid puncturing the pipe while preparing the surface with bristle blasters. Each pipe was then coated in epoxy primer and then wrapped so that the repair area had a minimum of two layers of coverage. Between these two pipes, approximately 260 square feet of surface was wrapped in carbon fiber fabric. The project was completed with a crew of only four people. In only five days these two pipes were wrapped; surface prep was done over two days and three days were spent applying the carbon fiber fabric.

Solution

Thanks to HydraWrap, the leaks were eliminated from these two vertical digester pipes. The pipes were given new strength, and the application will provide a layer of protection against future corrosion—all of this at a fraction of the time and cost associated with replacement.

Wrapping An 18-Foot Section Of Two Large Pipes

HYDRAWRAP CASE STUDY

![]() 1:25

1:25

Explore HydraWrap

Explore HydraWrap

More Products

More Products

Case Studies

Case Studies

Explore HydraWrap

More Products

Case Studies

Explore HydraWrap

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature