Addressing High Head Pressure

HydraTite® (Internal Joint Seal System)

Market

Stormwater

Challenge

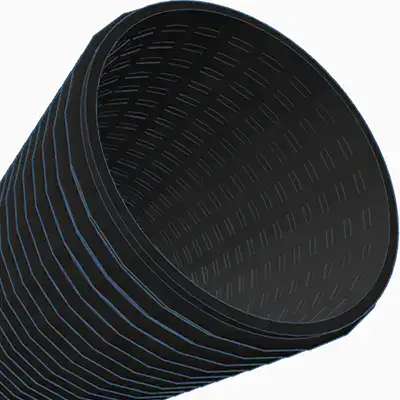

A plastic ADS pipe that manages stormwater for a business had developed many leaks despite the joints being in good condition. The high head pressure was forcing water through the joints. A repair was needed that would not disrupt the business above and that would be able to withstand the high head pressure.

Engineered Solution

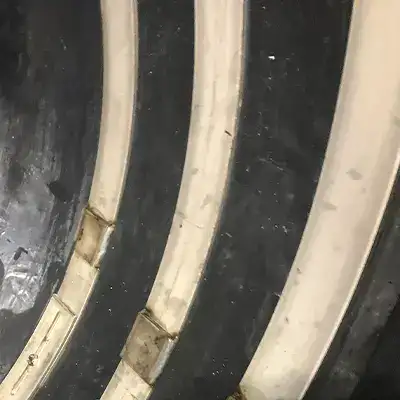

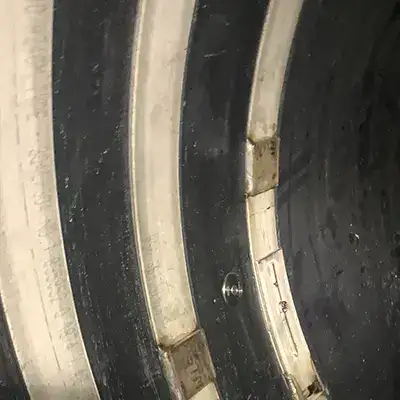

HydraTite Internal Pipe Joint Seals were the selected repair method to avoid excavation. Extra-wide seals would be installed with three retaining bands rather than the standard two. This would provide additional support against the high head pressure.

Scope

The pipe was clean and the interior surface was smooth and uniform. The rubber was positioned over each joint and the two outer retaining bands were installed to lock the rubber in place. Finally, the third band was expanded and locked in place between the initial two bands. Since there was no cleaning or surface prep required, the installation was completed faster than most. 25 seals were installed in 4 onsite days with a crew of only two people.

Solution

The repair was completed faster and with less disruption compared to dig and replace. These 25 joints were fortified against the high head pressure quickly using a solution that will last a lifetime.

Explore HydraTite

Explore HydraTite

More Products

More Products

Case Studies

Case Studies

Explore HydraTite

More Products

Case Studies

Explore HydraTite

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature