Cooling Water Piping Through Wall Leaks

HydraWrap® (Fiber Reinforced Polymer)

Market

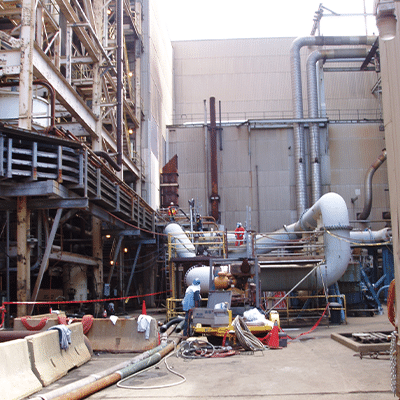

Power Generation

Challenge

The challenge was to rehabilitate the deteriorated cooling water piping due to through wall leaks.

Engineered Solution

The solution utilized the HydraWrap® Structural Composite Repair System.

Scope

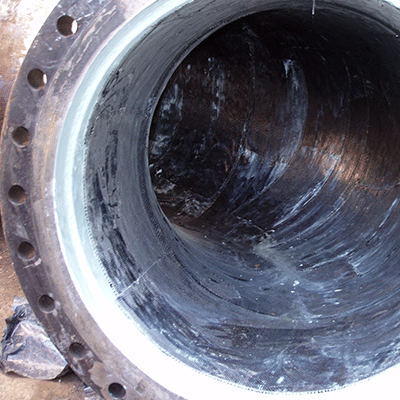

In 1987, sections of the cooling water pipe were replaced with carbon steel lined with Plastisol (plasticized PVC). Over the years, the liner disbonded from the substrate which subsequently resulted in numerous through wall leaks. These leaks and significant areas of corrosion resulted in poor system reliability and impacted the plant performance. Both the pump inlet and discharge pipe were affected by the deterioration.

Solution

In order to correct the situation, the plant needed to permanently restore pressure boundary and structural integrity within a normal 22 day maintenance outage, while minimizing the impact on the plant’s capital budget. Direct replacement of the piping was not a practical option due to time and budget constraints. The HydraWrap® carbon fiber system was chosen for its structural capacity, coupled with economical pricing and short installation window.

The project required the removal of the sometimes tenacious existing coatings. Selected pipe spools were removed and other openings were provided to allow access into the piping. The substrate was prepared by grit blasting. The piping system was repaired by applying an epoxy primer, layers of carbon fiber, and a top coat. The entire process was completed in the allotted time frame and was a cost-effective repair option.

Explore HydraWrap

Explore HydraWrap

More Products

More Products

Case Studies

Case Studies

Explore HydraWrap

More Products

Case Studies

Explore HydraWrap

More Products

Case Studies

OUR PRODUCTS

Trenchless Repairs Custom Made

OUR INDUSTRIES

From Power to Water We Have It Covered

OUR RESOURCES

Technical Data Sheets and Product Literature